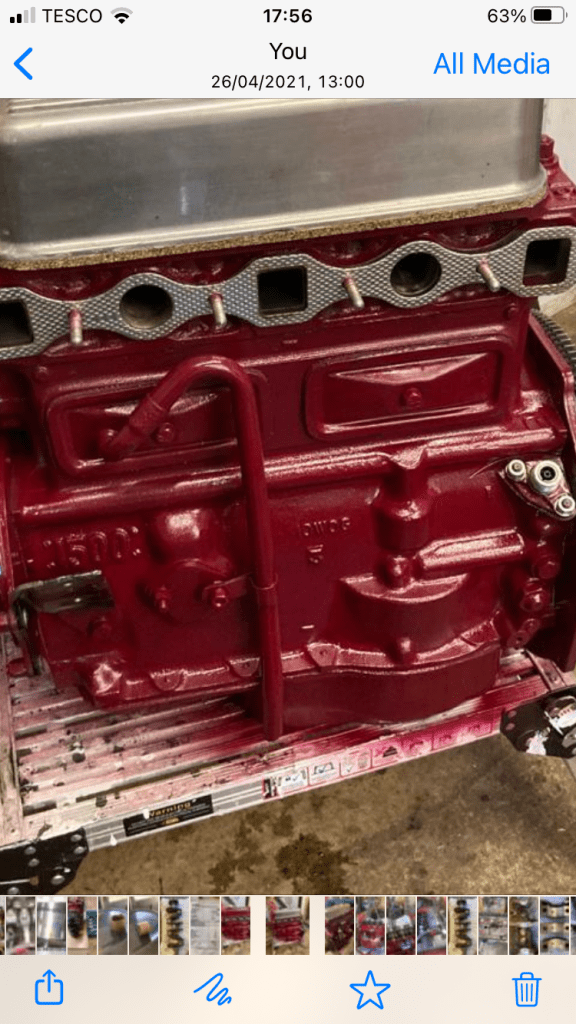

Since completing my own car, I’ve rebuilt two further 1500 engines and photographed much of the work. These might be useful references for others, so I’ve published them here.

On dismantling, several serious problems were clear that would at some point, lead to complete failure and are common B series failings.

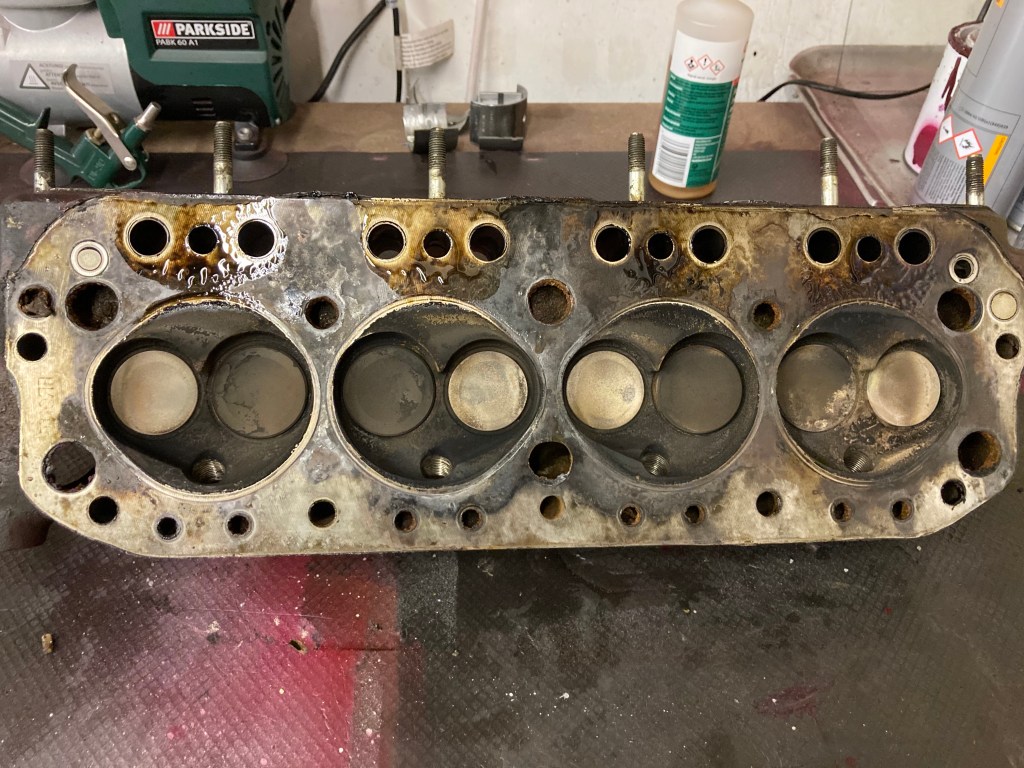

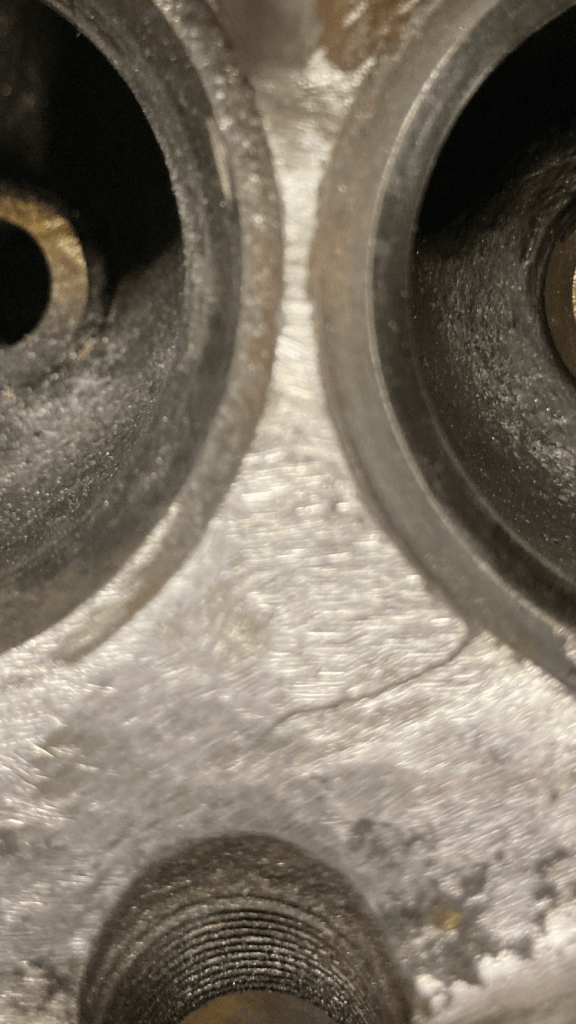

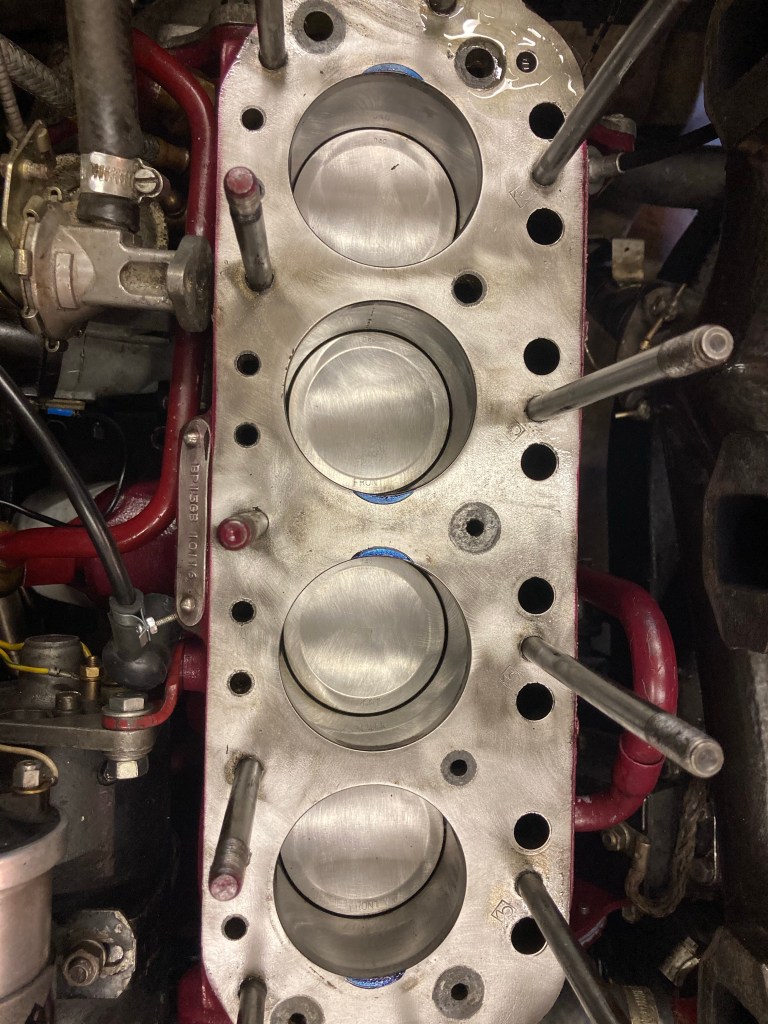

Cracked cylinder head – number 4 cylinder, between exhaust valve seat and plug aperture.

Badly corroded cam followers

Worn camshaft

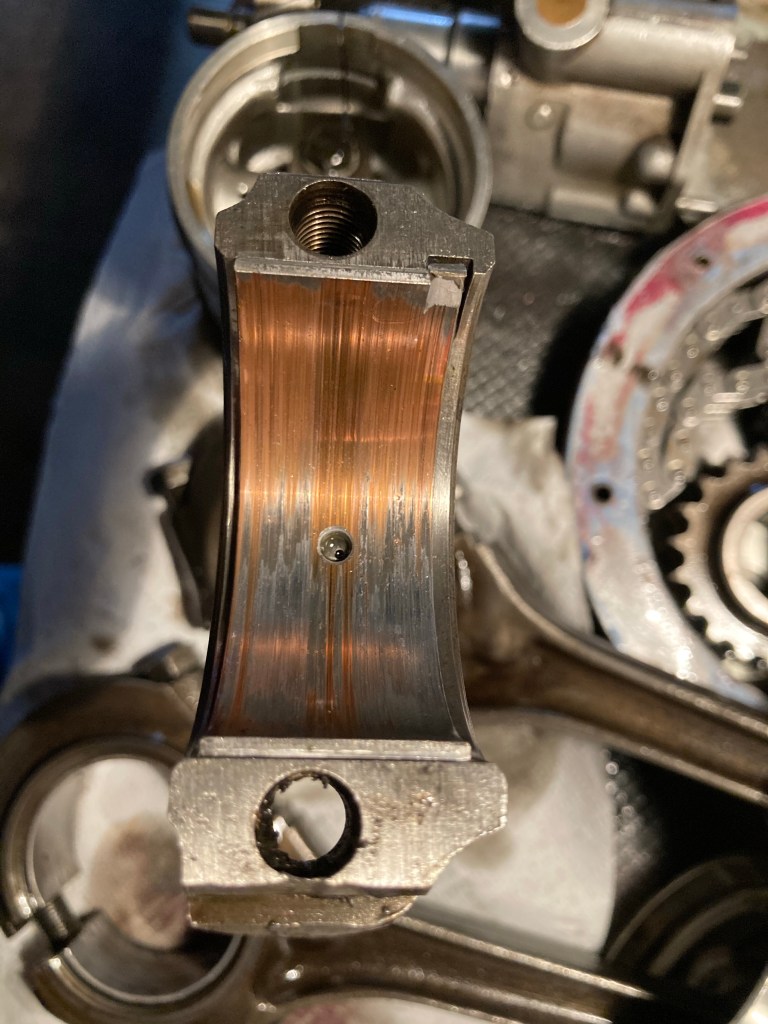

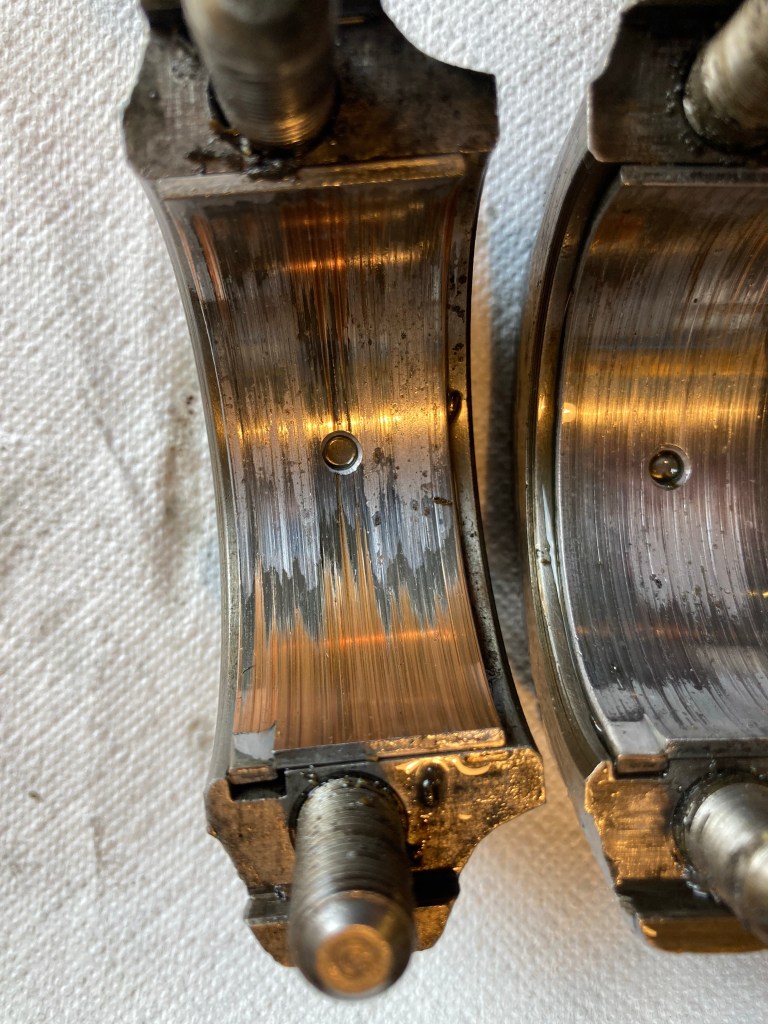

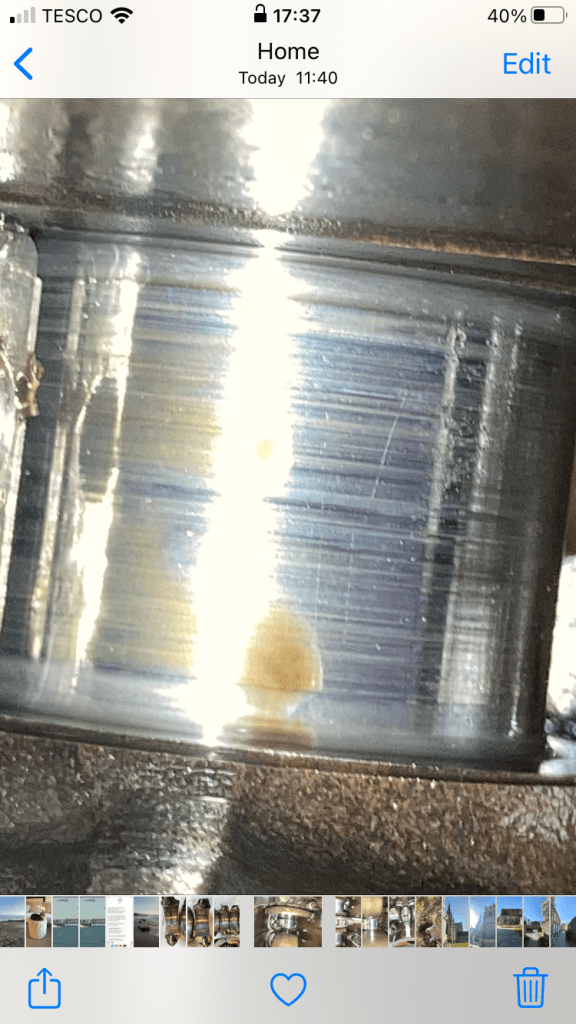

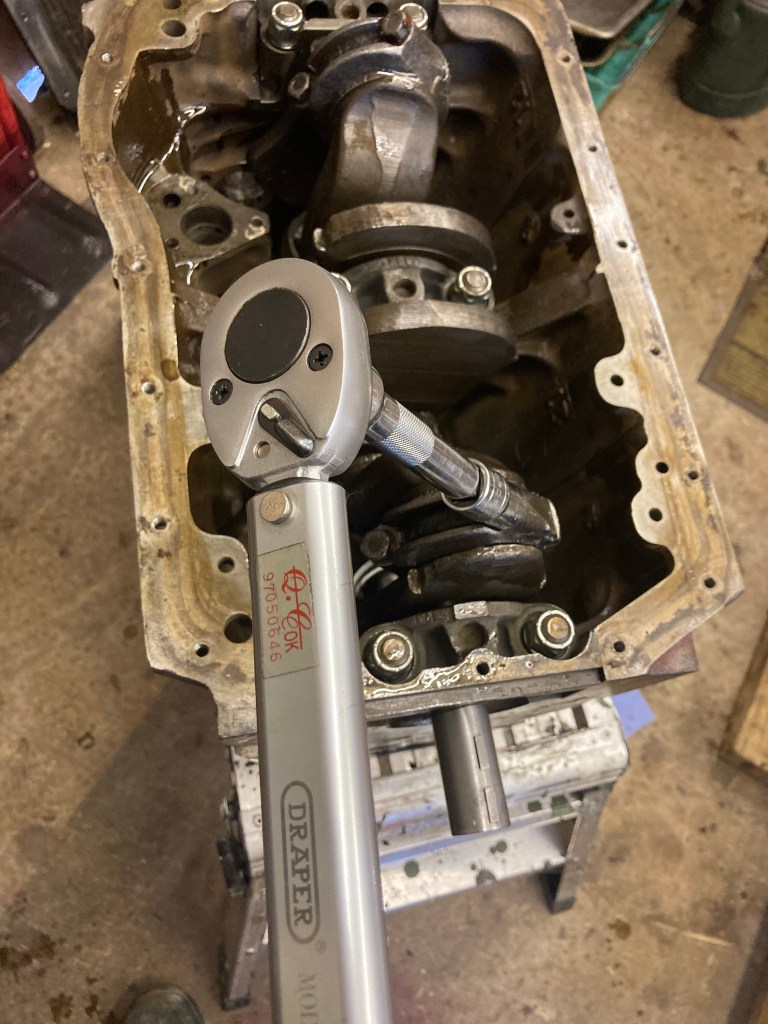

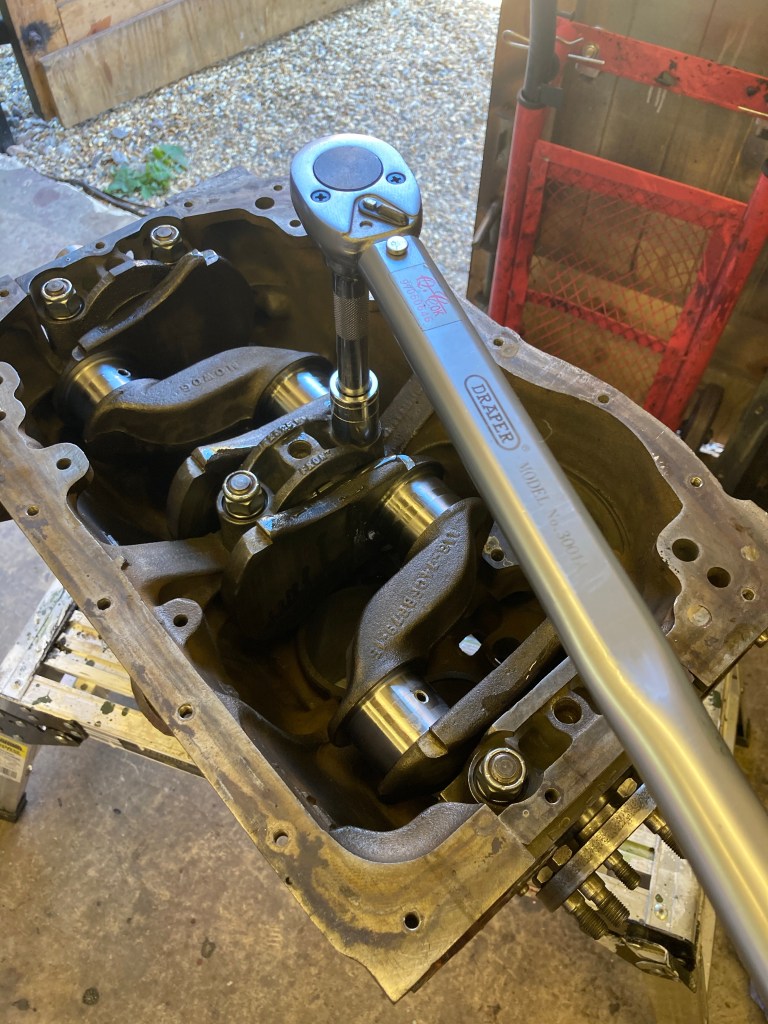

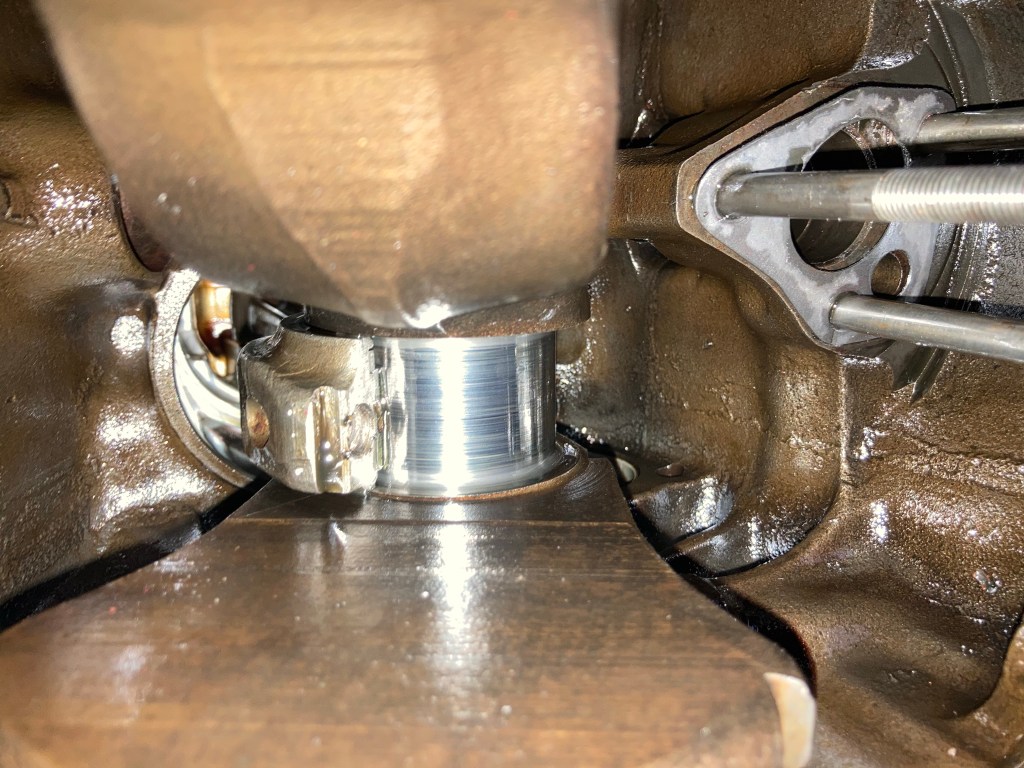

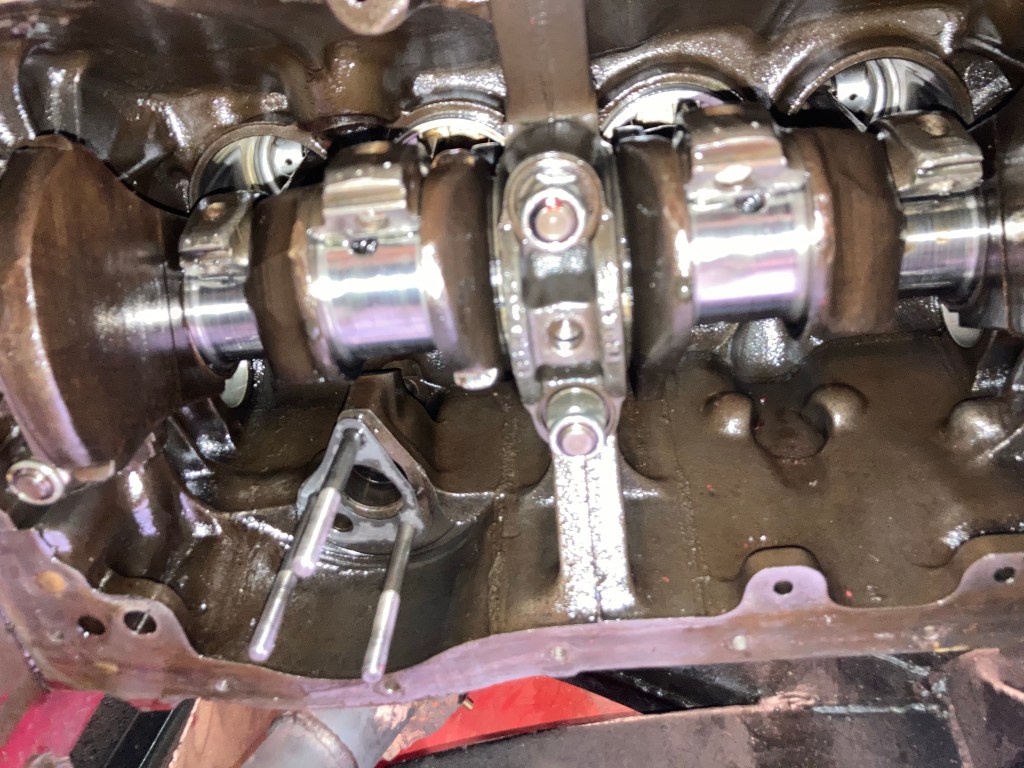

Badly worn crank and big end journals due to worn shells.

Collapsed flywheel spigot bush

Clutch centre plate worn to the rivets with minor flywheel scoring.

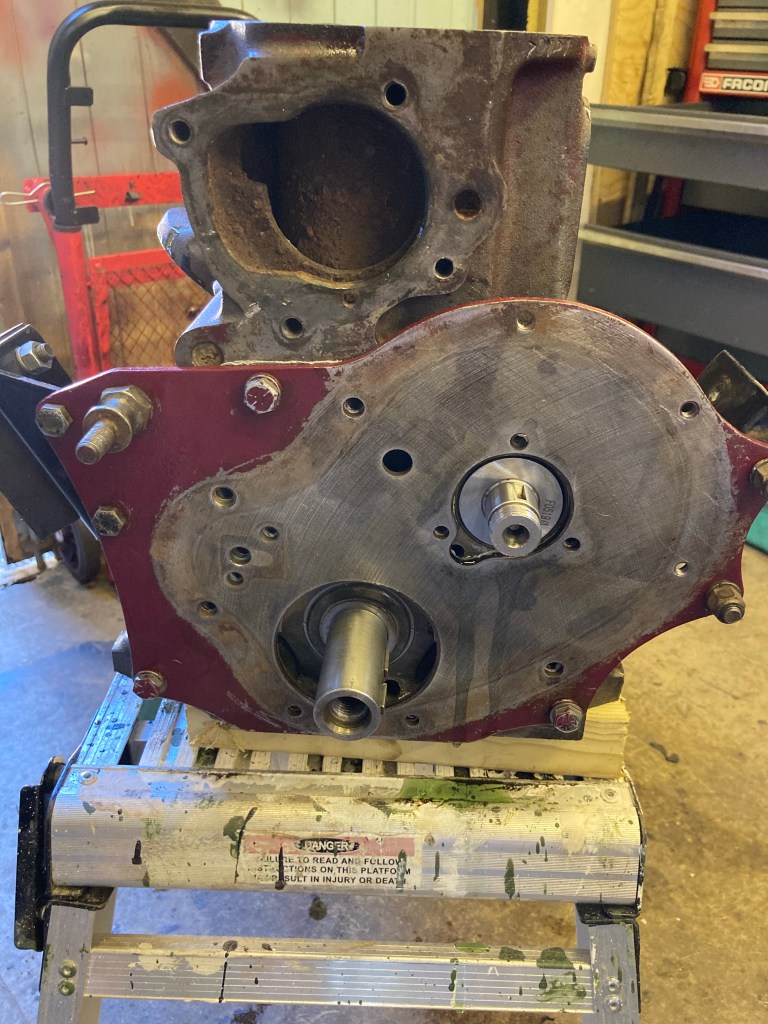

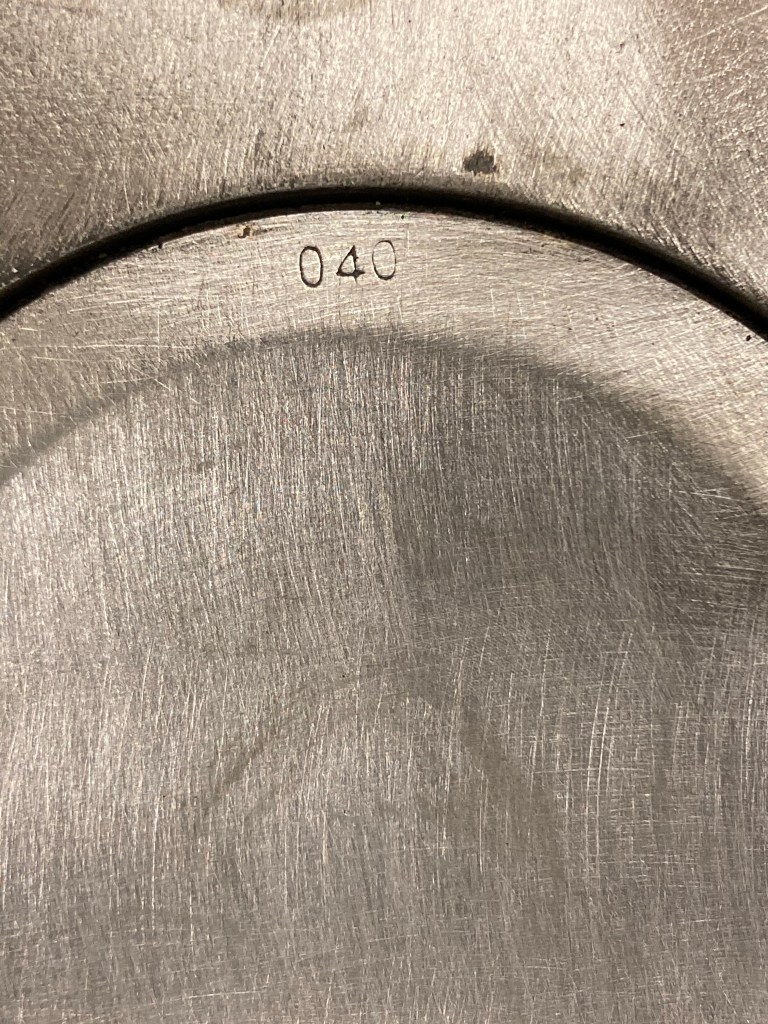

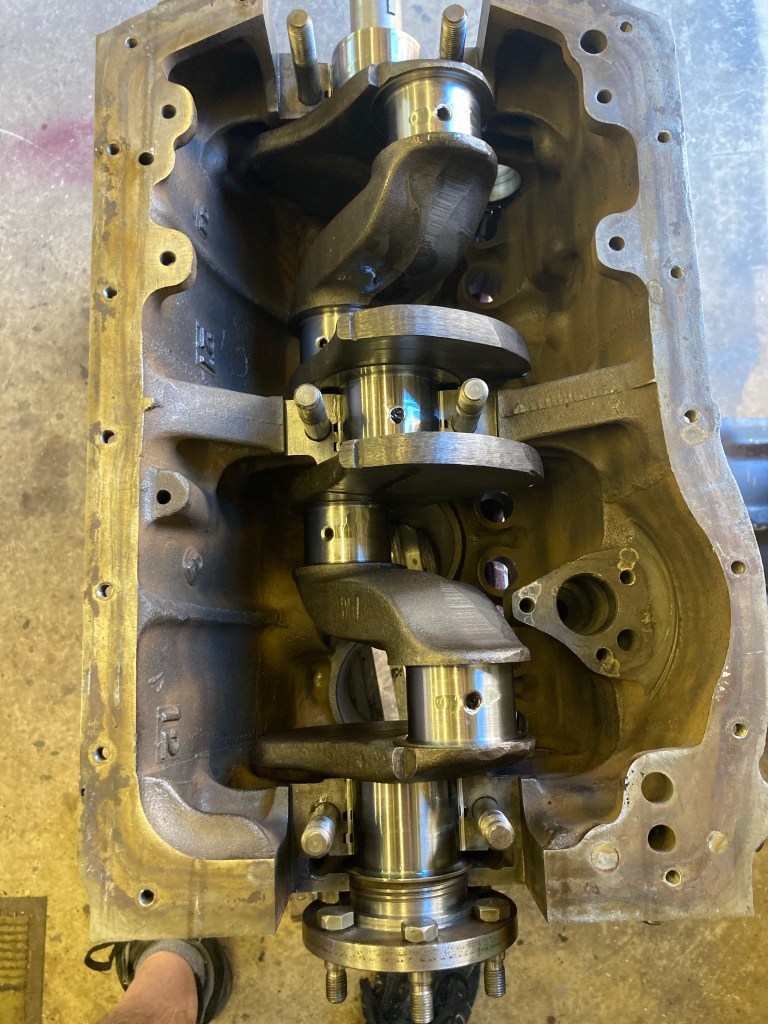

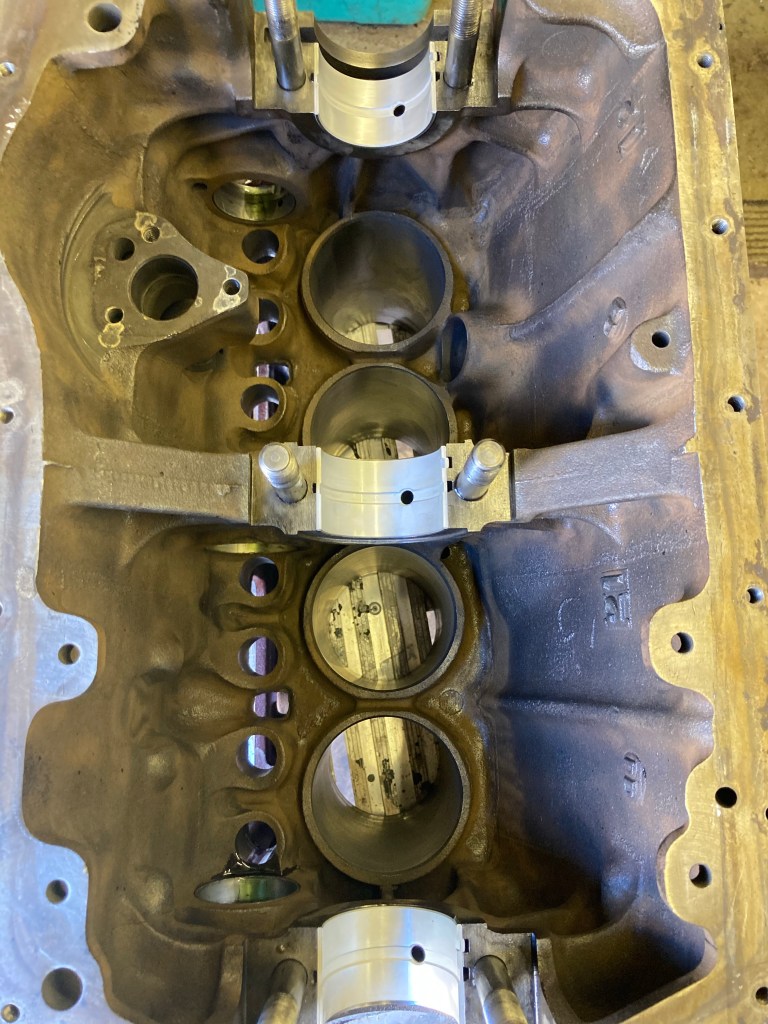

The engine was completely stripped and the crankshaft reground. The block was hot tank cleaned, with oilways and waterways thoroughly cleaned. The bores were honed.

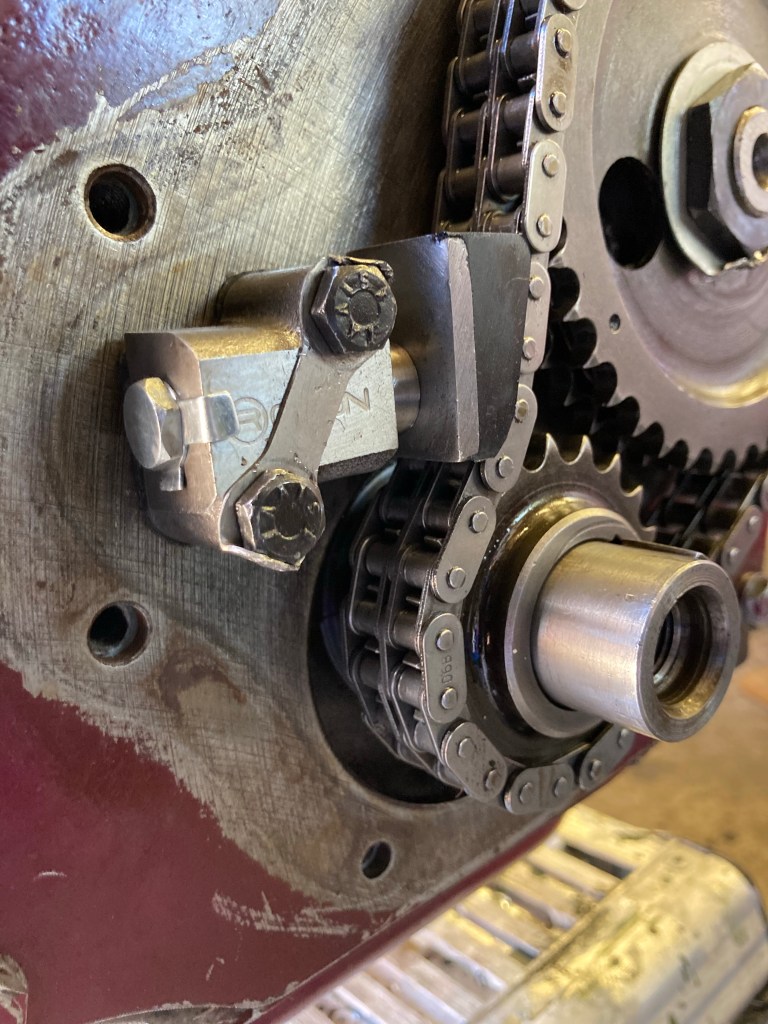

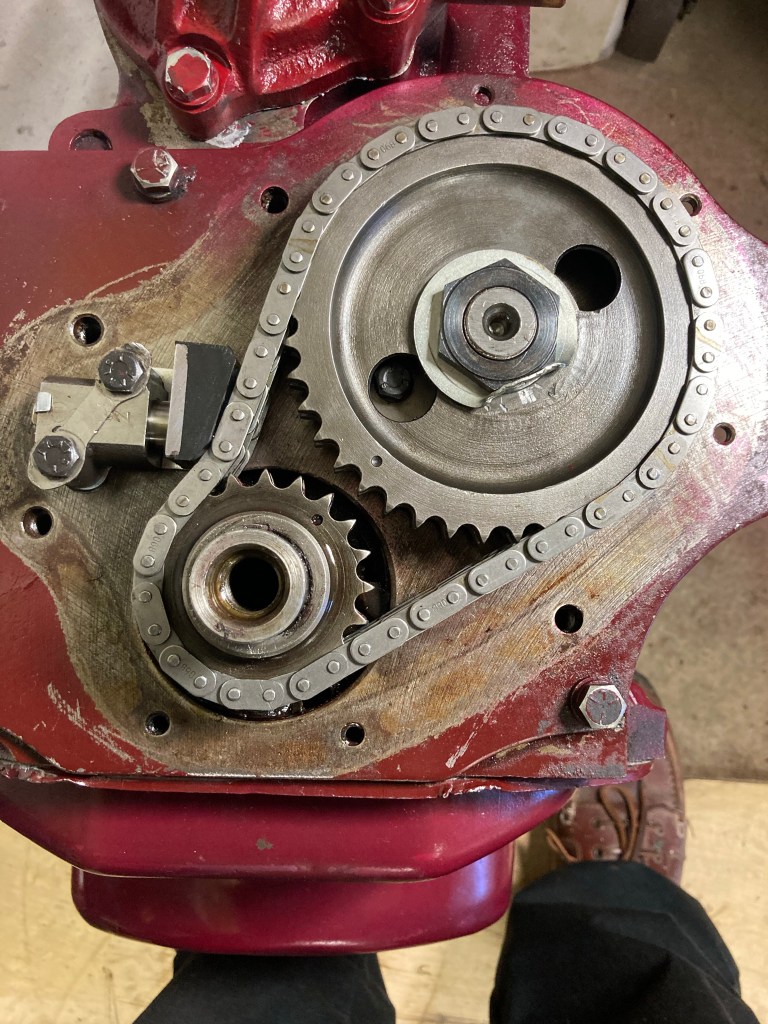

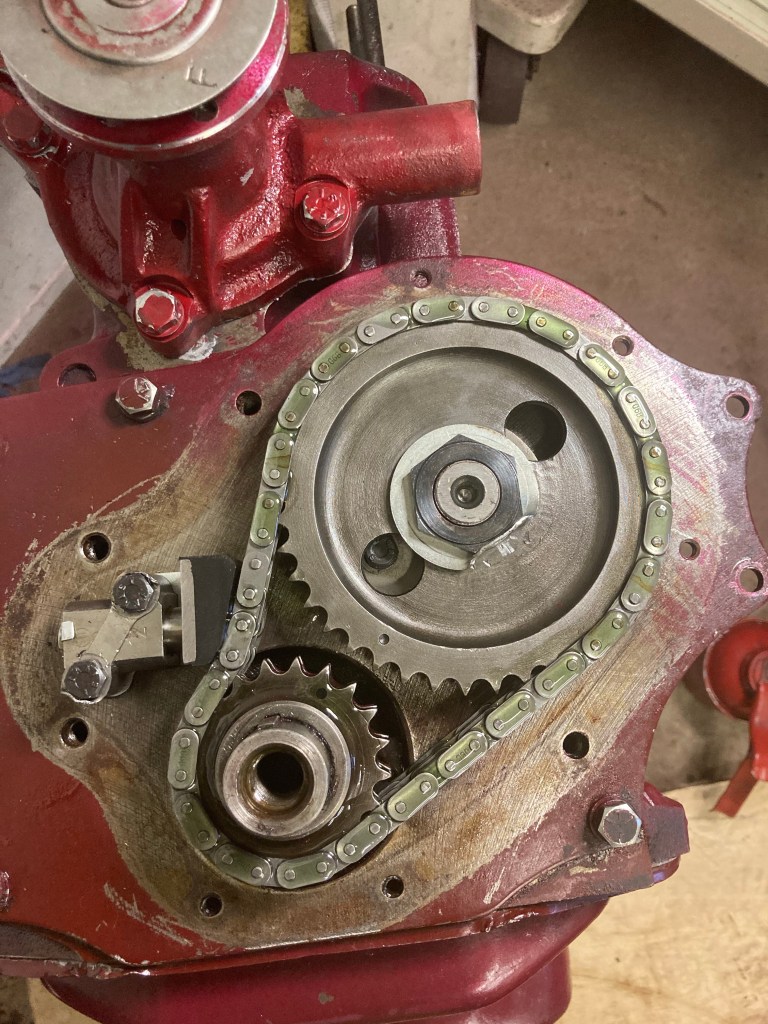

A new camshaft, followers, pushrods, timing gear, chain, tensioner and crank gear were fitted.

A new flywheel spigot bush was fitted and honed to fit input shaft.

A replacement unleaded head was fitted.

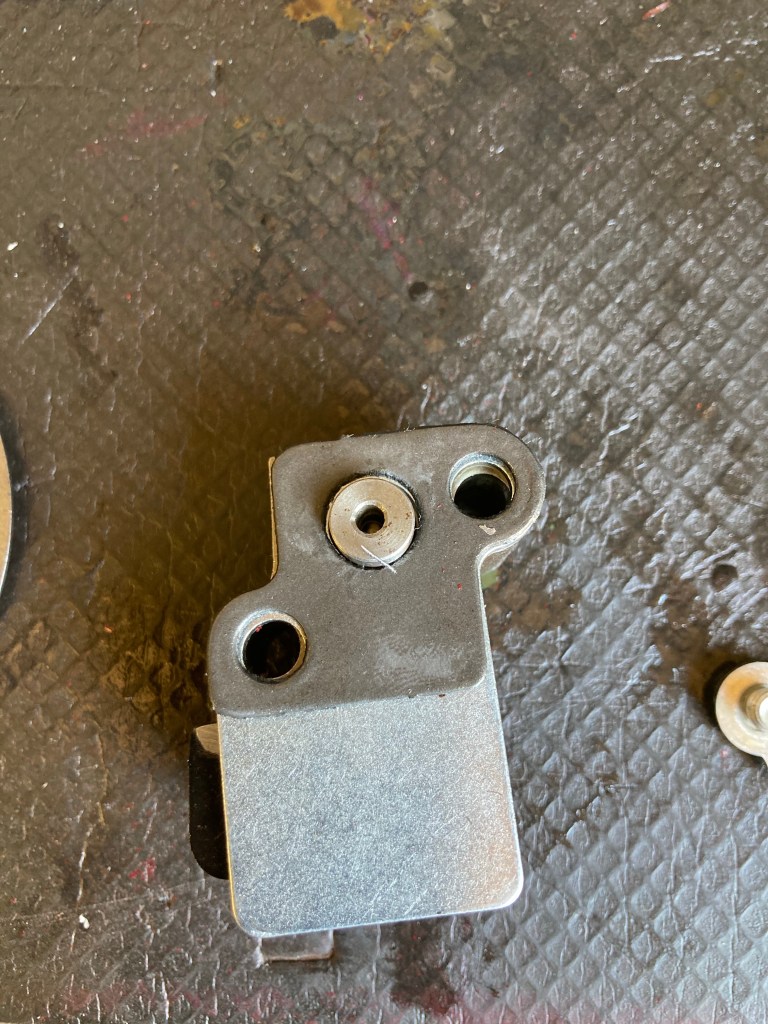

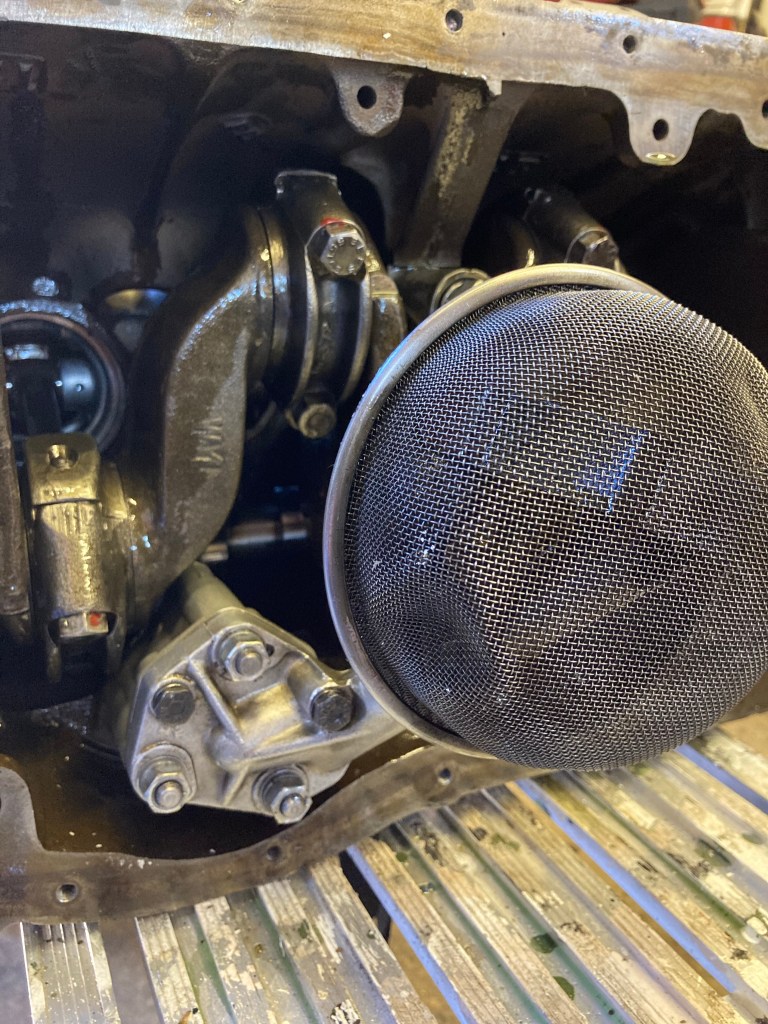

A spin off oil filter conversion was fitted.

New correct iron water pump fitted

New correct thermostat housing fitted

Fitted correct original rocker cover in place of aftermarket aluminium cover. Due to the lack of positive crankcase ventilation caused by the after market cover lacking the necessary ventilation tube, it is likely that an excess of acidic moisture in the engine, along with the leak from the cracked head, caused the damage to the various components.